United States

Dunn-Edwards Paints

Dunn-Edwards Paints asked for two separate mezzanines in an existing 300,000-square-foot building, as well as an addition for the bulk storage of raw materials for manufacturing. Accordingly, the team constructed a rail spur and two truck off-load stations for raw material to be pumped into a newly constructed bulk storage space. The facility also includes a retail area, corporate training, and board rooms, warehouse/distribution space, offices, a lab, and manufacturing area.

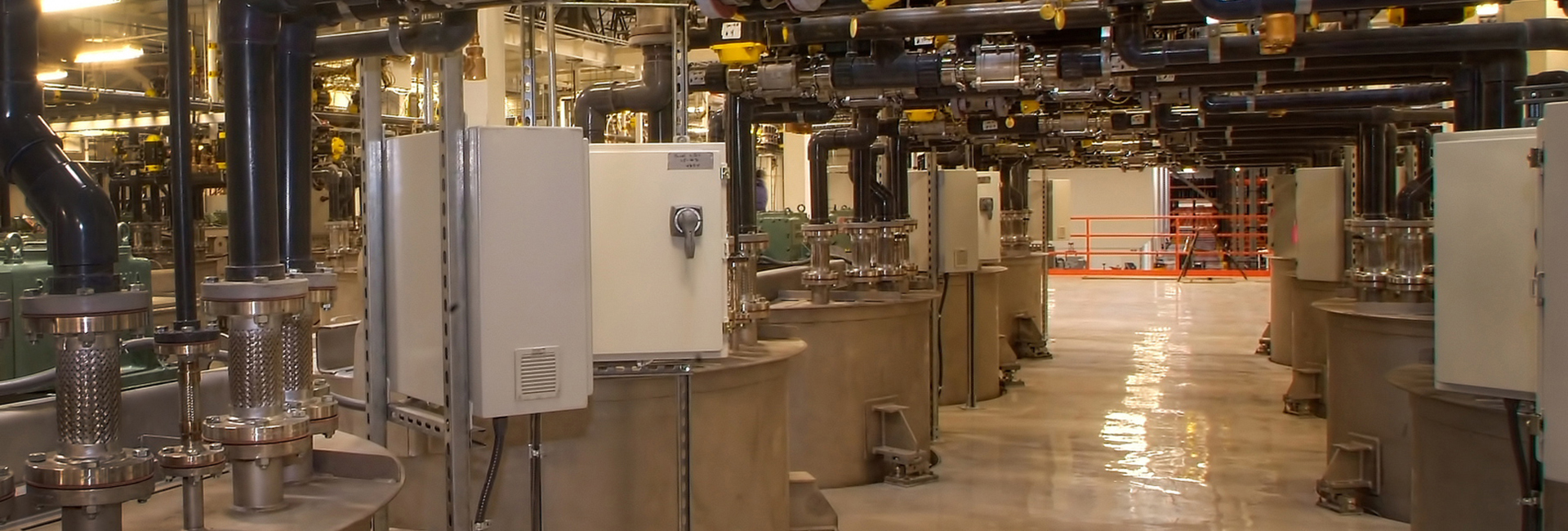

The manufacturing area is unique as the new mezzanine was built around some of the largest tanks while the remainder of the tanks are suspended from the mezzanine. Each tank is directly connected to load cells for weighing materials. There are more than 100 tanks used in the manufacturing process and more than 2,500 automatic valves connecting piping from the offload stage all the way to the fill lines where the paint is dispersed into cans. The project was designed and coordinated using BIM, which was crucial in coordinating the thousands of feet of process piping and conduit, the structure, and equipment.

The project included coordinating new equipment with the equipment relocated from existing facilities. Ultimately, the facility brings Dunn-Edwards’ paint manufacturing processes under one roof with distribution channels in place to make delivery smoother than ever. Prior to this facility’s completion, Dunn-Edwards had operations spread among several locations throughout the Southwest. The new facility will increase the company’s capabilities and make it easier to get products to customers in Texas, New Mexico, Nevada, Arizona, and California.

Architect

Deutsch Architecture Group

Client

Dunn-Edwards Corporation

Address

520 South 67th Avenue

Location

Phoenix, AZ

SF

350,000sf

Contract

CM/GC

Architect

Deutsch Architecture Group

Awards

2012 AZRE Magazine RED Award – AZRE Magazine; 2011 Best Industrial/Manufacturing Project Award of Merit – ENR Southwest

Certifications

LEED Gold