United States

Teamwork & Communication

Safety Story from Govan Brown’s Health & Safety Director

While walking a project for a site inspection, I came around a corner within the interior of the building and observed two trade partners working off the same A-frame ladder, one on each side. One person was standing on the bracing side without steps. When I approached the individuals, they climbed off the ladder and had the “Oh no, we’re caught!” look.

To help make sense of the situation, I communicated: “Gentlemen, you must tell me who the manufacturer of this ingenious two-person ladder is, as I want to place a large order for this product.” They both laughed and apologized for not taking the time to collect another ladder and reassured me it would not happen again as they realized how unsafe the act was.

When I visited that same project several times over the next few weeks, they welcomed my visits and were determined to avoid repeating the previous situation. We were able to have a frank and cordial conversation about any safety concerns or questions they had.

Using the Safety 360° approach, I acted as a coach, mentor, and friend by utilizing positive reinforcement and leaving a positive impact on the two gentlemen.

A Safety Story from a Layton Construction ESH Manager

During a project in Jackson Hole, Wyoming, we saw numerous injuries with one of our concrete trade partners. Bil Munck, vice president at Layton Construction, and I decided that Safety 360° training would be beneficial to help cultivate a strong culture built around safety. In June, we were able to get the entire crew together. Bil, another ESH manager, and I performed Safety 360° training for the trade partner.

Bil and I taught the classes in English while the additional ESH manager taught the classes in Spanish. We broke up the English classes into two groups. The first class was geared towards the trade partner’s upper management. The owner traveled up to Jackson Hole to attend the class. He immediately grasped the concept and showed good participation in the first class while sharing a personal story that hit home with his upper managers. The second class was held for all the field employees. The owner helped us teach the class by invoking participation from their employees. He shared a few personal experiences with his employees that resonated with them as well. By the end of the second class, the employees were engaged and asking pertinent questions. Our trade partner thoroughly enjoyed the training, and the owner asked if he could roll the training out to the rest of his company. Since this training occurred, I have seen a huge improvement in their safety culture. This trade partner has proven that the Safety 360° training does work. The biggest contributing factor was the owner grabbing a hold of the vision and teaching his employees to follow in his footsteps.

A Safety Story from an Ajax Regional Safety Manager

On April 14th, our site management team experienced what most would never want to happen on a jobsite. One of our subcontractor employees, a 37-year-old male, was having a medical emergency. With quick recognition and response to the emergency, this team made the necessary effort and saved a life.

Around 9:00am, a sub’s employee lost consciousness and was unresponsive on the jobsite. The workers around him quickly responded, calling the Ajax team to him within seconds. As Ajax staff recognized the urgency to immediately start CPR, another team member dialed 911.

One site manager continued CPR while another jumped to meet the rescue crew. Two other site managers grabbed the AED and ran to assist with CPR. With the two additional members, they moved the injured worker to a more manageable surface and continued to perform CPR. All the while this was happening and without prompting or hesitation, workers ran to form a line in groups, making a clear path to guide EMS to the worker in need. During the 15 minutes EMS was enroute, the team never gave up, giving everything they had to revive this worker. Due to their recent CPR training, persistence, and leadership, this team saved this young man’s life! Because of the collective teamwork from this jobsite, the young man is alive, walking, and talking under medical observation.

A Safety Story from a Structure Tone Dublin Managing Director

One of our operatives on a project collapsed while working on-site. Fortunately, the incident was witnessed by a site manager, who, with the assistance of another, immediately took action to aid the victim by administering CPR/AED defibrillation until the emergency services arrived on the project site. The emergency services then took over the resuscitation efforts. While all of this was happening, the site and design managers and our health and safety advisor immediately thought to manage the workforce on-site by having them stand down and by further keeping them informed as to what was happening, thus avoiding any unnecessary speculation.

Reacting decisively and without any hesitation while deploying first aid training, thinking clearly, and focusing on the priorities of aiding the victim very clearly led to his survival. Due to the quick actions that occurred to care for the individual, he was able to receive corrective heart surgery and expected to make a full recovery.

What occurred is an exemplary illustration of our Safety 360⁰ culture in action—where a life saved is to be celebrated.

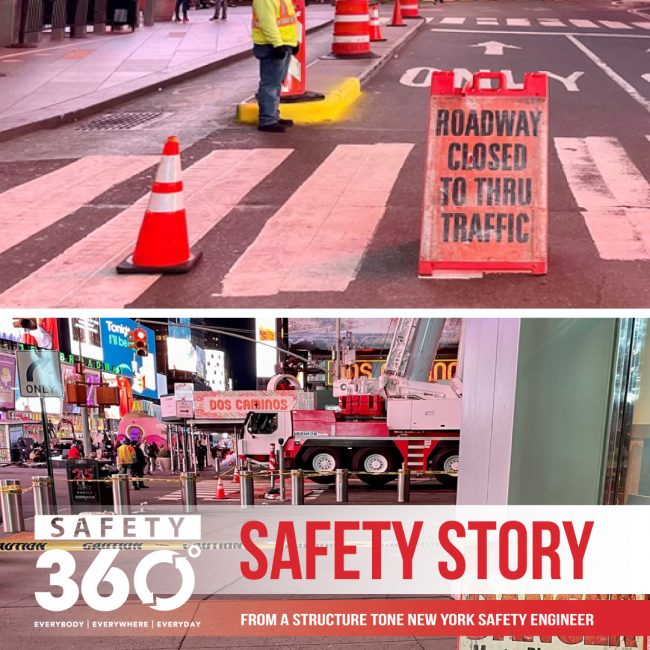

A Safety Story from a Structure Tone New York Safety Engineer

We had a crane pick scheduled in Times Square, which required closing the sidewalks and roads on the corner of West 47th Street and Broadway. This particular location made pedestrian safety a challenge as it is the most visited place in the country, in the city that never sleeps. As the area is packed with crowds throughout the year, there is never a good time to do this. To make things more difficult, there is a hotel entrance where the crane needed to be placed, and the entrance needed to remain accessible at all times. This posed a logistical challenge for the flagging crew and pedestrian safety. Five flaggers were stationed at different corners of the temporary construction area. However, some pedestrians were not pleased when informed they were not allowed through and had to take a detour. Many pedestrians tried to walk right through the temporary crane area, even after being flagged and instructed to go around. To prevent any potential confrontation, we placed directional signage and caution tape to make a clear pathway around the area. Oncoming pedestrians were then able to easily figure out where to go on their own while avoiding the need for interaction from the crane or flagging crew. Since the flaggers did not have a direct line of sight between each other, they were given radios to communicate with the crew of any potential issues or breaches. Once the crane and flagging crew were confident the area was properly secured and pedestrians were safe, they were able to get back to the job at hand without posing a hazard to the public. Teamwork, planning, and communication are vital when it comes to jobsite safety…not only for the workers but for the public around us.

A Safety Story from LF Driscoll’s VP of Ops Management

I was recently on-site visiting one of our projects that is pushing towards the finish line. Understandably, we had a number of areas and doors blocked off to allow for completion of floor finishes, in this case it was terrazzo. Add to that the fact that the space is broken up into a number of small galleries and rooms. As someone who is not on-site every day, I found myself asking, “If there was an emergency, would I know how to get out of here safely?”. Then it dawned on me that even workers who are on-site every day, and had been for some time, may not be aware of these detours and blocked exits. Therefore, exit routes that they had become accustomed to may not be available.

On every one of our projects, the final design establishes safe means of egress for the eventual building occupants. Life safety plans defining these routes are usually the first pages of the design documents. But, during construction, when we’re dealing with any number of temporary conditions and other “in progress” factors, it’s easy to lose sight of the need to have clear and safe routes of exit for workers in the event of an emergency—and this isn’t just a jobsite issue. At the beginning of the year, our safely professionals developed new signage and communications to raise awareness of appropriate exit routes from our Bala Cynwyd office building.

Each time you walk your jobsite, think about how workers could evacuate the site quickly and safely in the event of an emergency. Post simple exit signage and make this a topic at foremen’s meetings and at orientation. As conditions change, make corrections and update the information accordingly and make sure there are safe exit ways that can accommodate a large number of exiting workers. Conduct fire drills periodically, especially as the workforce grows and new trades are coming on. Like many other topics we address when discussing safety, it only takes one event or a brief second to end up with a serious problem. At the same time, just a little thought can prevent one.

A Safety Story from an LF Driscoll Superintendent at Penn Medicine

As construction sites across Philadelphia and the surrounding areas began shutting down in mid-March, the Penn Medicine team was gearing up. Together with our partners, we worked in three shifts around the clock to temporarily shift the focus of the PavilionGo to https://stobuildinggroup.com/projects/penn-medicine-pavilion/ construction to provide additional space for treating patients, if the hospital needed it.

We started building on March 23rd and turned the finished space over to Penn Medicine on April 6th. The effort by the men and women who accomplished this was nothing short of miraculous. It really proves what can be done when you’re called to step up. Continued meetings with the crews before each shift was huge. Those discussions really communicated what needed to be accomplished, and how to get it done SAFELY. It truly took everyone working together to make this happen as quickly as it did.

By working in three shifts, we were able to keep the men and women distanced as needed—and the more information we received about the virus, the more we adjusted our safety strategy. Today on our job, only five people are allowed in an elevator at once and each car has sprayed footprints on the floor, so the workers know where to stand. We’ve also limited the jobsite access to two entry points, where we have infrared scanning, along with a daily sign-in sheet that must be completed before entering the site. The workers are given a different colored bracelet to wear each day, so we know everyone has badged-in properly. Once construction on the Pavilion starts up again, we’ll be working in two shifts to limit the amount of people working within 6ft of one another.

A Safety Story from Ajax Building Corporation’s Safety Director

A few years ago, Ajax was working with a particular steel erector for the first time on a project in Charlotte County. Whether it was getting everyone to wear their PPEGo to https://stobuildinggroup.com/safety-stories-ppe/ or enforcing proper fall protectionGo to https://stobuildinggroup.com/safety-stories-fall-protection/ practices, making sure the foreman and crew were working safely was a daily struggle. Throughout the project, we held numerous meetings to discuss safety compliance, and when that failed, we were forced to start sending crew members home for violating site safety requirements. We even assigned a full-time safety coordinator to the project, specifically to monitor this crew.

About two years later, we were starting another project in Pinellas County. Market realities at the time dictated that we expand our base of steel erection subcontractors, so we hesitantly hired the same steel erector. We conducted a pre-construction safety meeting with them prior to starting and—as luck would have it—the same foreman and crew who had been on the last project were also assigned to this project.

During the meeting, I went through all the usual safety topics and the crew was fully engaged. Afterwards, the foreman pulled me aside and told me a serious incident occurred on the project immediately following their first job with Ajax. The event motivated them to hire a full-time safety director and develop safety training programs for all workers. “That accident opened our eyes, but it started with you guys,” the foremen said. “Ajax and your insistence on us working safely made us a better company.”

They ended up being one of the top subcontractors on that project and are now one of our “go-to” steel erection subcontractors.

A Safety Story from LF Driscoll’s Safety Director

A few weeks ago, one of our large healthcareGo to https://stobuildinggroup.com/sectors/healthcare/ clients had a major water leak in an area of the hospital we weren’t working in. Fortunately, the leak was not on a patient floor, but it was heading towards a room that housed countless dollars of computer equipment that would shut down medical operations if they got wet. One of our painters responded quickly and stayed until the leak was fixed over 45 minutes later. We tell our clients that the collective “we” are here to assist at any time—and our painter proved it. He went above and beyond to ensure the safety of thousands of patients that day.

A Safety Story from Govan Brown’s Director of Health & Safety

At Govan Brown, we were engaged on a significant commercial project alongside another general contractor. Both parties issued a notice of project, but the other contractor was onsite many months before us, so they took on the role of constructor.

From the start, we both operated as a team—especially when it came to safety. Together, we worked to ensure all workers received safety orientations from both of our companies before stepping foot onsite. The Govan Brown team had also been attending our fellow contractor’s Joint Health & Safety Committee (JHSC) meetings. We were in constant communication with the other organization’s site safety team to ensure we were all doing everything in our power to keep our workers safe.

This situation is quite unheard of. In fact, the Ministry of Labor deemed it a precedent-setting arrangement. The other contractor was hired by the client, and Govan Brown was hired by the tenant. Therefore, we worked within the same building and spaces, but operated separately. The way we integrated our safety programs in this unique situation demonstrated that two companies with the same safety values can work together to provide a safe workplace for all.